38 6

52 4 4 Schuppen

52 4 4 Schwert

52 6

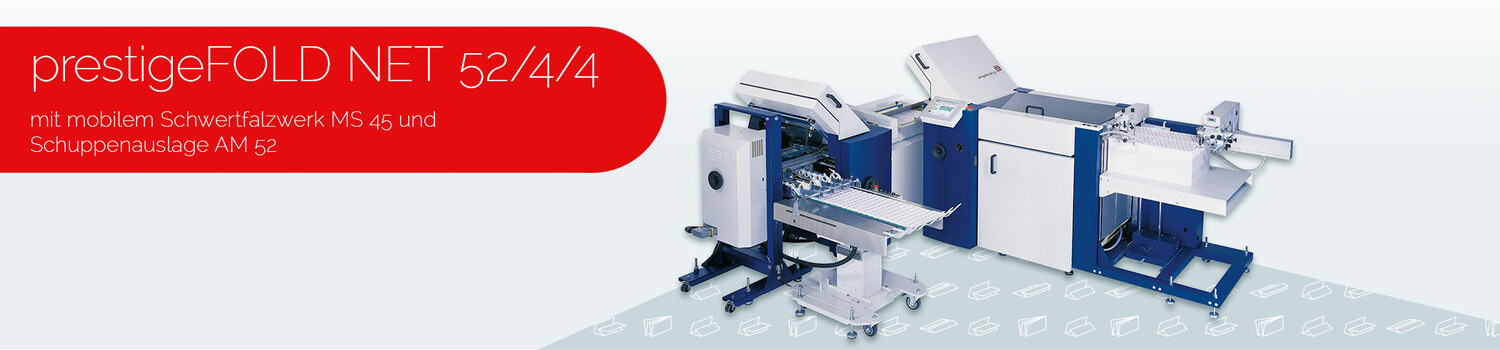

Versatile applications for different requirements.

Fast and reliable feeding is always guaranteed. The suitable technology makes sure that a large variety of materials and formats can be processed.

Thick or thin products, glossy or matt surfaces, single cut sheets or signatures, open or closed edges, cards or brochures are no problem for the feeding systems fromMBBäuerle. No matter whether the feeder magazine is full or whether only a few products are left - separation is functioning smoothly. This is made possible by a principle that creates optimal conditions during separation.Although the actual quantity in the magazine is changing, the contact pressure remains the same.

The different types of feeders are suitable for stand-alone operation and also for integration into systems.

The flat pile feeder FSA is particularly suitable for loading units from other manufacturers. The integrated alignment track guarantees the highest feeding accuracy.

The feeder makes it possible to load the online folding system with either cut sheet or continuous forms from the roll. This means that the folding machine can be integrated completely into the workflow of a continuous digital printing system, but it can also be used for all other traditional folding jobs. The feeder is adapted to the respective application within a very short time and thus offers a maximum flexibility for the user. A high stacking capacity and as well as simple operation are other advantages of the system.

Paper sizes:

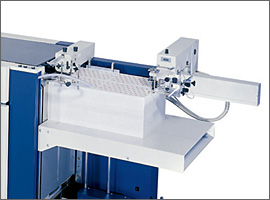

Mobile bottom-feed, top-load air feeder with independent drive.

Separates single sheets and in connection with the Interface 32/C

also continuous forms.

Paper sizes:

By using the BSA 5000, the stacking capacity of a bottom-feed,

top-load air feeder becomes practically unlimited. The BSA 5000

continuously monitors the height of the paper stack in the feeder and

automatically replenishes paper after a minimum height has been

reached.

Paper sizes:

This versatile feeder covers a great variety of applications.

The multifeed 3602 guarantees fast and reliable paper feed

in any application.

Paper sizes:

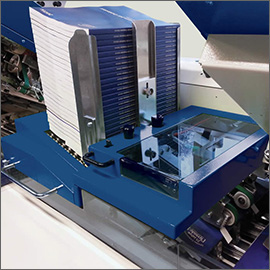

Thick or thin inserts, glossy or matte surfaces, single or multi pages, open or closed edges, cards or brochures are no problem for the standard suction feeder, because products are separated pneumatically. It does not matter whether the feeder magazine is loaded to capacity or is down to a few sheets, there is always reliable sheet separation. This is made possible by a new design that guarantees consistent pressure at the feed point regardless of the weight of product in the hopper.

Paper sizes:

With the catalogue feeder even inserts with a product thickness of up to 15 mm can be handled without any difficulties. As an option, it is also possible to equip the catalogue feeder with a loader to ensure a continuous and smooth supply of material.

Paper sizes:

The Pick & Place feeder allows the damage-free separation and positioning even of special inserts such as product samples or candy bags. This ensures that a very wide range of materials can be processed.

Paper sizes: